Chrome Plating

Chrome plating plastic injection moulded products is a process that involves applying a thin layer of chromium onto the surface of the plastic product to give it a shiny, metallic appearance. The process starts with the preparation of the plastic surface by cleaning, etching, and applying a primer coat. The plastic part is then electroplated with a thin layer of copper, followed by a layer of nickel, and finally, a layer of chromium.

Chrome plating creates a mirror-like finish that is both durable and resistant to corrosion, making it ideal for use in the automotive, aerospace, and consumer products industries. Plastic products can also be chrome plated to create a variety of finishes, such as satin or brushed, depending on the desired effect.

While the process is more complex than other surface finishing options, such as painting or printing, chrome plating provides a higher level of durability and can add significant value to your plastic product. However, it is important to note that the process can be more expensive and requires specialised equipment and expertise.

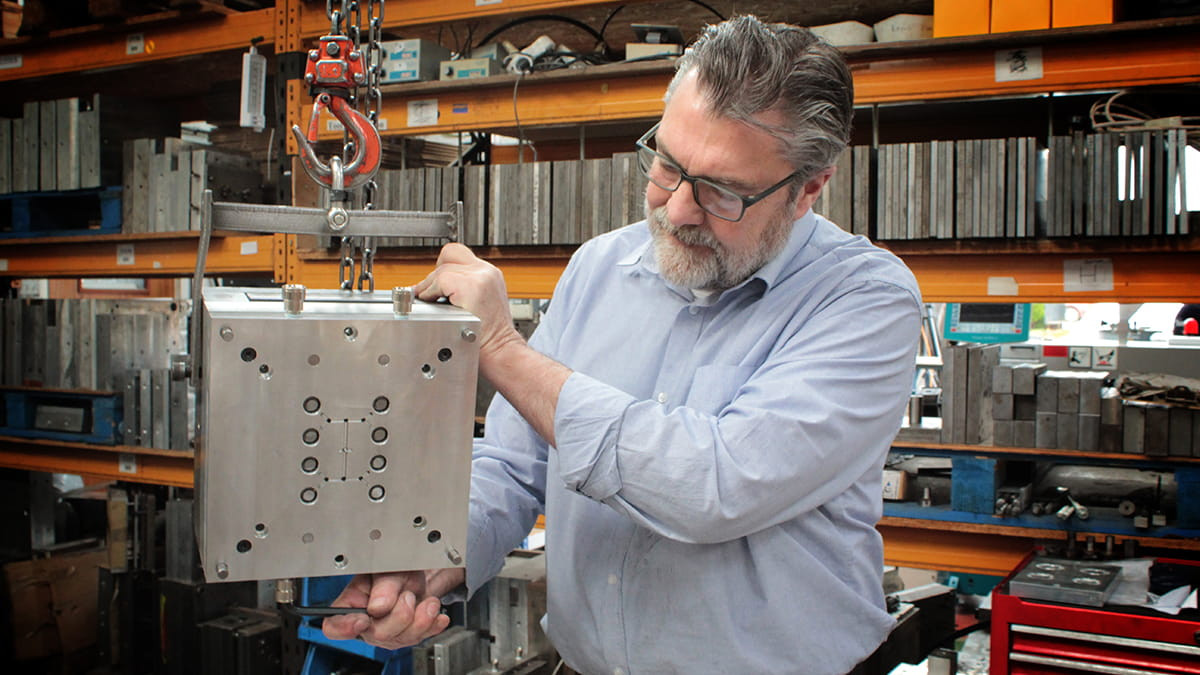

At Great Central Plastics, we have many years of experience in this process, and we regularly manufacture products that require a chrome-plated finish, especially badges for the automotive sector. The chrome-plating of plastic products creates a premium-looking effect, making it an attractive process for the projects that warrant it.

Please get in touch if you wish to discuss your chrome-plated plastic projects.

Get a Quote