Chrome Plated Badges

What are Chrome Plated Badges?

Chrome plating for car badges is a crucial process that serves both decorative and functional purposes in the automotive world. This specialised surface treatment enhances the visual appeal of car badges and crests while providing increased durability and resilience against environmental factors.

Car badges are essential to the brand image of every vehicle manufacturer on the planet, representing the vehicle's brand, model, or unique features. These badges can be found on various parts of the car, including the grille, fenders, bonnet and boot.

Aesthetic Enhancement: Chrome plating for car badges involves applying a thin layer of chromium onto the badge's surface. This process applies a mirror-like finish, elevating the overall appearance of the badge. The reflective properties of chrome create an eye-catching, polished look that complements the vehicle's design and branding with a high-quality metallic-like finish.

Durability and Protection: Beyond aesthetics, chrome plating adds a protective layer to car badges. It shields them from environmental elements such as moisture, UV rays, and road debris. This protection helps maintain the badge's shine and prevents corrosion, ensuring a longer lifespan for these injection moulded automotive badges.

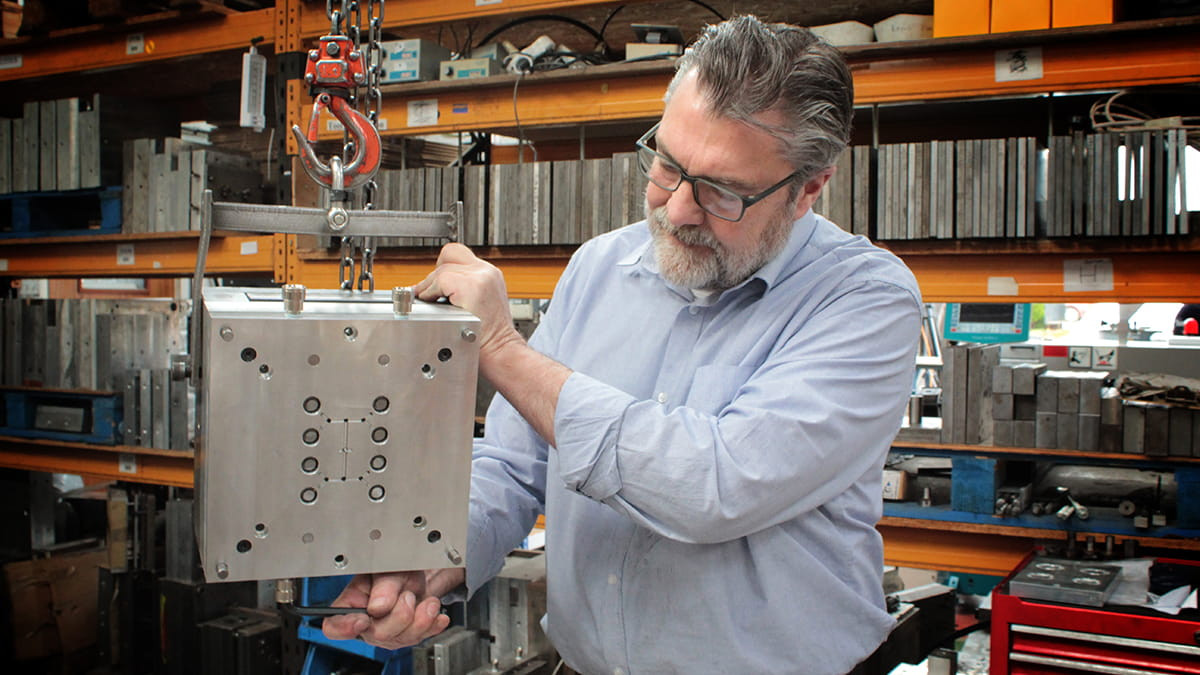

How are Chrome-Plated Car Badges Manufactured?

Surface Preparation: The process begins with the careful preparation of the badge's surface. This involves cleaning, degreasing, and polishing to ensure an even flawless finish.

Electroplating: Electroplating is the core of the chrome plating process. The badge is submerged in a chromium bath, and an electrical current is applied. This current causes a layer of chromium to bond with the badge's surface, creating the iconic and permanent chrome finish.

Quality Inspection: Each chrome-plated badge is meticulously inspected for imperfections, ensuring it meets quality standards regarding appearance and adhesion. The injection moulding and chrome plating processes must uphold the highest quality levels. If there are any imperfections from the injection moulder, this will directly impact the finished quality of the chrome plating.

Additional Finishing: Depending on the desired result, additional processes like buffing or clear coating may be applied to enhance the badge's shine and longevity further.

How do Chrome-Plated Badges Differ from Painted Badges?

Chrome plating is a more cost-effective and generally a better-recognised finish for OEM badges, with chrome-styled badges becoming the industry standard for many manufacturers.

However, chrome plating is limited to a mirror-like silver finish, which may not always be desired.

Spray painting automotive badges allows for a wider option of colours and finishes, including gloss and matte. These painted badges are increasing in popularity in the modified vehicle sector, with some major automakers also adopting a matte black painted finish for their high-end or luxury models, for example.

CHROME-PLATED BADGES AT A GLANCE

- WEATHERPROOF

- INCREASED QUALITY

- IMPROVED AESTHETIC

Chrome-Plated Badge Applications

Chrome-plated car badges are widely used by original equipment manufacturers (OEMs) to enhance their vehicles, reinforcing brand recognition and adding a touch of luxury.

Additionally, there is a growing market within the modified car sector to personalise vehicles with customised or bespoke chrome-plated badges to elevate their appearance. These aftermarket designs can add a distinct look to your vehicles, and with our low MoQs, we are ideally suited to short and medium-volume runs, as well as full production runs for OEM brands.

Many different vehicle types utilise chrome-plated badges and crests, such as cars, trucks, motorbikes, trailers, farming equipment, industrial vehicles, and more.

Experience the Great Central Plastics Difference

When you choose Great Central Plastics, you gain a reliable partner committed to delivering exceptional results that can guide you throughout every step of your manufacturing journey.

Our expertise in bespoke injection moulding, cutting-edge technology, wide material selection, and customisable finishes ensures that your unique requirements are met with the highest levels of sustainability, precision and excellence.

With minimum order quantities as low as 100 for bespoke wheel caps and chrome-plated automotive badges (depending on final design), the Great Central Plastics team is flexible, experienced and ready to discuss your automotive moulding project.

Elevate your vehicle's appearance with chrome plated car badges. Contact us today!